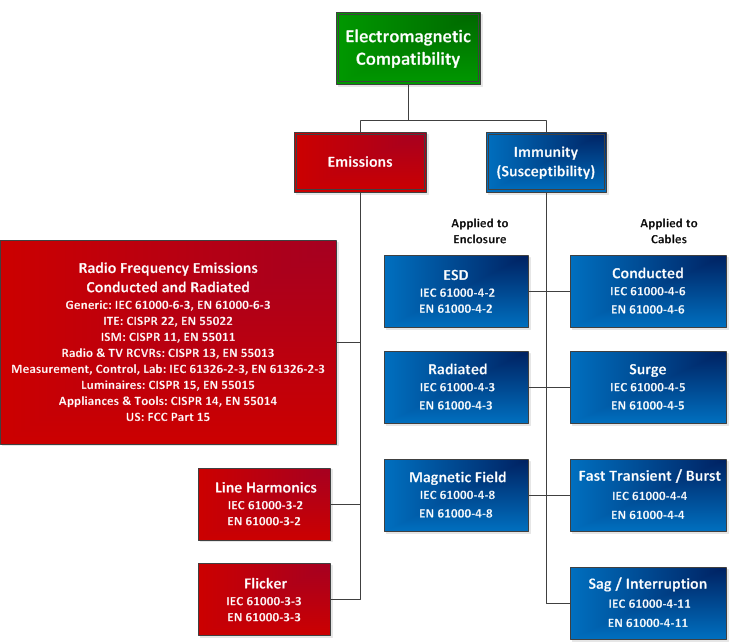

True Power Research provides electromagnetic compatibility (EMC) consulting expertise for electronic power supplies. To help our clients with a better understanding of the divisions of electromagnetic compatibility, see the Electromagnetic Compatibility Chart:

The acronyms EMC-EMI are often used interchangeably where the acronym EMI means “electromagnetic interference”. However, EMC is actually the ability of a piece of equipment to operate without producing EMI which disrupts other equipment, and the ability of a piece of equipment to operate in the presence of potentially disruptive fields or conducted transients. Electronic power supplies are a major source of conducted and radiated emissions. Additionally power supplies are usually at the front end of equipment and must bear the brunt of conducted transients and providing immunity for the equipment from line sources.

EMC-EMI Definitions

Noise — Any unintended electrical signal, either produced or received by the equipment under test.

Interference — Any noise which produced by the equipment under test which creates a disturbance in other equipment or any externally produced noise which disturbs the equipment under test.

Emissions — Noise emanating from the equipment under test. This noise can be conducted along cables, or radiated from the enclosure.

Immunity — The ability of the equipment under test to operate without being disturbed by external fields or conducted transients.

Susceptibility — The capability of the equipment under test to respond to unwanted external fields or conducted transients. Susceptibility is the opposite of immunity.

EMC Components

To help with quickly grasping the components of electromagnetic compatibility. See Fig 1.

Emissions

Emissions is noise emanating from the equipment under test and can be either conducted or radiated.

As shown in the electromagnetic compatibility chart, emissions can be of the following three types:

- Radio Frequency — Noise generated by high frequency components of switching action and generally subject to limits at 9kHz and greater. Radio frequency noise is either in the form of radiated emissions from the chassis or conducted emissions. Conducted emissions are often transformed into radiated emissions from the cables as the cables become effective antennas as longer lengths. International standards, US, and European standards regulating radio frequency noise are:

- Generic: IEC 61000-6-3, EN 61000-6-3

- Information Technology Equipment (ITE): CISPR 22, EN 55022

- Industrial, Scientific, and Medical (ISM): CISPR 11, EN 55011

- Radio and Television Broadcast Receivers: CISPR 13, EN 55013

- Measurement, Control, and Laboratory Equipment: IEC 61326-2-3, EN 61326-2-3

- Lamps and Luminaires: CISPR 15, EN 55015

- Household Electrical Appliances and Portable Tools: CISPR 14, EN 55014

- United States equipment: FCC Part 15

- Line Harmonics — Noise generated at multiples of the line frequency and subject to limitations in the interest of maintaining line quality. Standards: IEC 61000-3-2, EN 61000-3-2

- Flicker — Very low frequency effects upon the line voltage caused by low frequency events in the equipment under test. This type of interference typically causes objectionable variations in lighting.Standards: IEC 61000-3-3, EN 61000-3-3

Electromagnetic Immunity / Electromagnetic Susceptibility

As defined above, immunity is the ability of the equipment under test to operate with out performance degradation in the presence of external fields or conducted transients. Immunity is the opposite of susceptibility, but both describe a piece of equipment’s response to ext. Immunity compliance is now required in the European Union. With certain exceptions immunity compliance is not required in the United States — the thought being that immunity is self regulating in that a product which is not immune to external fields and conducted transients will not sell well in the market place. However, in the past couple of years certain high profile events such as the Toyota vehicle malfunctions, may be motivating a change in the laws regarding immunity compliance, at least in the cases of products involved with consumer safety.

Events testing the immunity of equipment are applied to either the cables or the enclosure:

- Electro-Static Discharge (ESD) — This a test of the ability of the equipment under test to absorb an electrostatic impulse to the enclosure. Standards: IEC 61000-4-2, EN 61000-4-2

- Radiated Immunity / Radiated Susceptibility — The response of equipment to the presence of external radiation from communication devices applied to the enclosure. Standards: IEC 61000-4-3, EN 61000-4-3

- Magnetic Field — The ability of the equipment to operate in the presence of powerline magnetic fields applied to the enclosure. Standards: IEC 61000-4-8, EN 61000-4-8

- Conducted Immunity / Conducted Susceptibility — The response of equipment to the presence of conducted noise from nearby equipment and transmitters via the cables. Standards: IEC 61000-4-6, EN 61000-4-6

- Surge — The ability of the equipment to operate while surge voltages are applied to the cables. These types of events can be caused by large inductive load turning off, or lightning strikes. Standards: IEC 61000-4-5, EN 61000-4-5

- Fast Transient / Burst — The ability of the equipment to operate while repetitive burst transients are applied to the cables. These types of events are often caused by inductive load switching. Standards: IEC 61000-4-4, EN 61000-4-4

- Sag / Interruption — The ability of the equipment to operate or survive a sag or momentary interruption in the line voltage cable. Standards: IEC 61000-4-11, EN 61000-4-11

Regional Concerns for Electromagnetic Compatibility

Requirements for EMC compliance may differ depending on where the product is sold. “Reference standards” are produced by organizations such as Comité International Spécial des Perturbations Radioélectriques (CISPR) and International Electrotechnical Commission (IEC). However, these reference standards only become law when they are adopted by a country’s law making body. As a result compliance requirements may differ from country to country.

Type of Market

The type of market may require use of specialized standards. Military applications often have there own standards for compliance. In the United States the standard for compliance is MIL-STD-461 and it covers most emissions named above. Immunity is worded in terms of susceptibility instead. Medical devices usually have their own standards as well.

Type of Product

IEC has a generic standard for electronic products. However, if there is a more specific standard available for the product, that more specific standard must be used. Such an example is CISPR 15 for luminaires.

Basic Concepts to EMI Suppression by Design

- Include Electromagnetic Compatibility Considerations early in the design

- Minimize noise generating sources

- Control the medium over which noise is conducted or radiated. EMI filters are commonly employed for controlling conducted emissions, and shielding for controlling radiated emissions.

- Arrange noise receptor to minimize pickup

Our Services for Power Supply EMI-EMC Compliance

Sucessful EMC and EMI compliance requires thoughtful design from the early in the development cycle to be able to pass emission testing without requiring an expensive redesign. Without this thoughtful design, it is almost guaranteed that expensive redesign and retesting will be needed before a successful pass.

We are well versed at designing power supplies that comply with regulatory standards for EMC-EMI Compliance. If your product is required to meet regulatory standards for electromagnetic compatibility, we have the expertise to help you. Call or email us for help with electromagnetic compatibility design.

Additional References about General EMC Compliance

For additional information about Electromagnetic Compatibility standards, an excellent resource is the dBi Corporation webpage on EMC Standards.

For an excellent general text on EMC compliance, see the text Electromagnetic Compatibility Engineering by Henry W. Ott. While some the references in this text are outdated due to rapidly changing standards, the principles taught are sound and very applicable.

EMC Testing Facility: EMC Integrity in Longmont, CO. Vincent Greb, Owner.

Share the Knowledge!

If you benefited from the information on this web page, please share it with others. You have our heartfelt thanks!