True Power Research is a power electronics consultant and provider of custom power supply designs.

Power Supply Design Reviews

We provide power supply design review services of new and existing designs for original equipment manufacturers. In general, the design review is a critical milestone task in the development of any engineering project and should be accomplished at the completion of the paper design, and prior to beginning any printed circuit board layout, ordering parts (long lead time parts excepted if the schedule is compressed), or beginning any prototype build. The goal is to identify any of the following:

- specification compliance and performance issues,

- excessive component stress

- design improvements,

- potential cost reductions.

Introduction: Cost of Fixing Design Errors

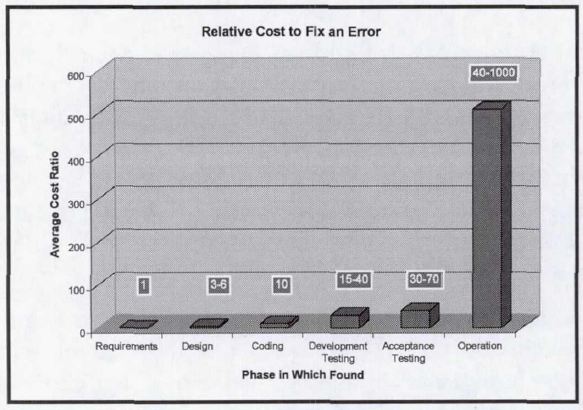

For engineering products in general, it is roughly estimated that the costs of fixing a design errors increase by a factor of ten for every stage in the product development. This exponential increase occurs because each stage of the development cycle is built upon the foundation of the earlier stage.

In the development of electronic power supplies, if an error is caught while in the paper design stage, the cost to repair might realistically be $10. If the error is caught while in prototype testing and requires a change to the printed circuit board along with a prototype rebuild and re-testing, the cost to repair might be on the order of $5000 or more, the exact cost depending upon whether or not the PCB needs to be revised to accommodate the needed change and how much testing needs to be repeated with the revised prototype. If the error is caught during the product qualification stage, the cost to repair might be on the order of $15,000 or more depending on how much qualification testing is involved and how much of the qualification testing must be repeated after the error is corrected. If the error is caught after the production processes have been designed, then the cost to repair increases by however much the processes might need to be changed.

In the worst case, if the error is caught after the product has gone out to the field, the cost is tremendous, and is enough to completely wipe out any profit for the project and to actually cause a loss for the project as well customer relations problems.

A NASA researcher named Barry Boehm studied this effect in the early 1980’s. Here is a pictoral summary of his findings:

A recent example of design error repair cost is Intel’s chip error with the Sandy Bridge chipset. The error went unnoticed till after product was shipped. The estimated cost to repair was about one billion dollars.

The latest example of design error repair cost is the lithium-ion battery failure on the Boeing 787 Dreamliner. As of this time, the total cost to Boeing and subcontractors is to be determined. But it is not going to be small.

The lesson for designers and project managers is to put extra effort and time early in the design cycle to root out errors when the cost of fixing them is very low. Design reviews are intended to help with rooting out these errors while in the paper design stage.

Design Review by Unbiased Third Party

Occasionally a client of a power supply vendor will desire an objective and unbiased third party design review of the product to ensure the product is designed to meet specifications and/or that it is of robust design. We have experience with providing third party design review services and will provide a detailed and thorough report of specification compliance and/or design robustness. Even if you are developing your own product and are desiring an unbiased and objective source of expertise — we are ready to help you.

Web Generated Designs

Electronic equipment manufacturers often use web based design tools provided by vendors of power supply controllers. These tools are advertised to greatly reduce the design effort, cost, and time to market for developing power supplies for OEM products. While many OEM’s find success with these tools, the following points about using web-based tools should be considered:

- Only basic designs are accommodated.

- Only the most common topologies are available.

- Isolated topologies are usually not available. A couple of vendors offer basic flyback topologies.

- Designs use only proprietary controllers. There is no possibility of using a controller that is second sourced.

- Proprietary controllers are often poorly documented and difficult to understand.

- The designs need to be critically reviewed for fundamental errors.

- The designs typically provide only schematic, BOM, and some performance data. There is no component stress data available.

- If the design doesn’t work properly, the manufacturer is left holding the bag, unless they have some knowledge about power supply design.

- Parasitic parameters, critical to switching power supply performance, are usually ignored.

The web-based approach sounds good, but it often has hidden and unpleasant surprises. We can provide robust product designs for you, or we can provide critical design review services for you if you opt to use web-based design tools.

While we cannot guarantee that you will have a bug free design after the critical design review, we can help identify as many potential problems as possible while the design is still on paper and mistakes are inexpensive to fix. If you are in the prototype testing stage, and experiencing problems, please see our troubleshooting services page.

Performance

We can perform design reviews to evaluate basic power supply performance parameters important to the application. The parameters are evaluated at the corners of the operating points of input voltage, output current, and ambient temperature. We will also review specific performance parameters that you identify to us.

Component Stress

During a design review, component stresses will be evaluated and any components close to or beyond the manufacturer’s rating will be identified. If you specify derating guidelines, we can check component stress level compliance with the guideline.

Design Improvements

As part of a design review, we can also provide design improvement recommendations to improve performance and robustness.

Cost Reductions

As part of a design review, we can provide design change recommendations for cost reduction. Our standard approach is to identify the most costly parts as determined by cost per device multiplied by number of instances followed by an evaluation of cost reduction potential while still ensuring performance and robustness.

Information Disclosure

Design reviews require substantial information disclosure. The following pieces of documentation will be required:

- specifications and application information,

- schematics,

- wiring diagrams,

- costed bills of material with reference designators and parts counts,

- custom part datasheets,

- magnetics source control drawings,

- printed circuit board Gerber files if the PCB have been laid out.

Missing documents will result in incomplete design reviews.

Please call or email us today to arrange a design review for your power supply design.